What Does TPO Roof Stand For?

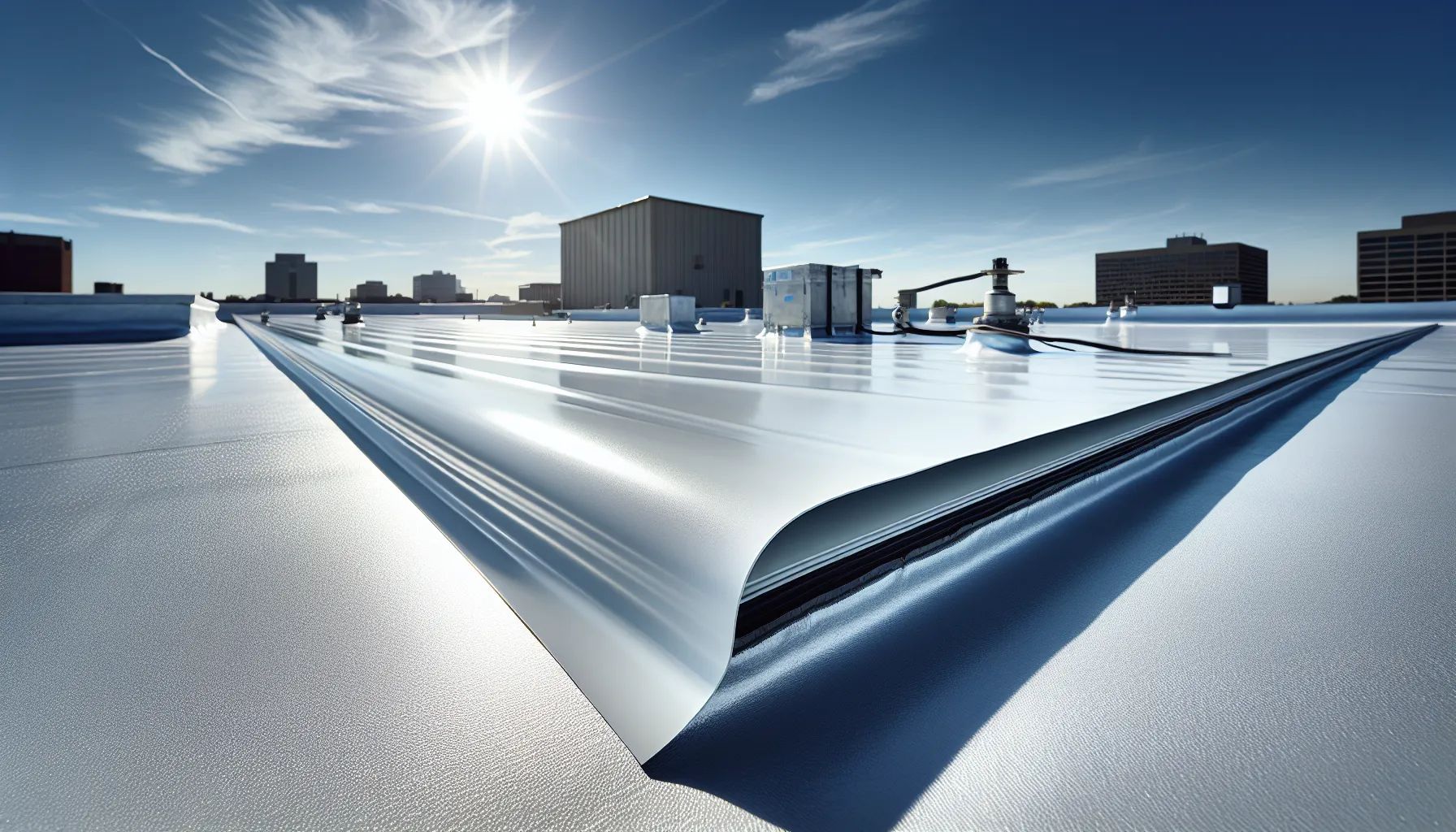

TPO roof stands for Thermoplastic Polyolefin roof, a single-ply roofing membrane that has become one of the fastest-growing choices for commercial flat and low-slope roofs. If you've ever wondered why so many building owners choose this material over traditional options, or what makes it different from other roofing systems, you're not alone. We often encounter questions about TPO's composition, performance, and whether it's the right fit for specific projects. In this text, we'll break down everything you need to know about TPO roofing, from its chemical makeup to its real-world applications, so you can understand why it's earned its place as a go-to solution in modern commercial construction.

Understanding TPO: Thermoplastic Polyolefin

TPO is a synthetic rubber roofing material that blends polypropylene and ethylene-propylene rubber to create a flexible, durable membrane. We see it used primarily on flat and low-slope commercial roofs because it offers an excellent balance of performance and affordability.

The "thermoplastic" part of the name tells us something important: this material can be heated, welded, and re-heated without losing its properties. That's different from thermoset materials like EPDM, which cure into a permanent shape. The "polyolefin" part refers to the polymer family that includes polypropylene and polyethylene, materials known for their chemical resistance and stability.

What makes TPO particularly interesting is how it combines these polymers with rubber components. This hybrid approach gives the membrane both the flexibility needed to accommodate building movement and the strength to resist punctures and tears. We've found that this combination works exceptionally well in environments where roofs face UV exposure, temperature swings, and occasional foot traffic.

The Chemical Composition of TPO Roofing

The membrane itself contains several key components that work together to create its performance characteristics. Polypropylene forms the base polymer, providing strength and chemical resistance. Ethylene-propylene polymers add flexibility and low-temperature performance. Color pigments, usually white or light gray, reflect sunlight and reduce heat absorption.

UV absorbers are mixed into the formulation to protect against sun damage, which is critical for any roofing material that sits exposed all day. Flame retardants help the membrane meet building codes for fire resistance. Additional fillers and reinforcing agents are added to achieve specific physical properties like tensile strength and elongation.

We should note that TPO formulations can vary between manufacturers. Some use more polypropylene for increased stiffness, while others add more rubber components for better flexibility. This variability means not all TPO membranes perform identically, which is why material selection matters when planning a roofing project.

How TPO Roofing Membranes Are Manufactured

TPO membranes are produced in controlled factory settings where precision matters. The process starts with combining the polymer blend, polypropylene, ethylene-propylene rubber, and various additives, in large mixers. This mixture is heated and extruded into sheets of specific thickness, typically ranging from 45 to 80 mils (that's about 1.1 to 2.0 millimeters).

A critical step involves adding a reinforcing layer called a scrim. This synthetic fabric, usually made from polyester or fiberglass, is embedded between layers of the TPO compound. The scrim provides dimensional stability and tear resistance, preventing the membrane from stretching excessively or ripping when stressed.

The manufacturing process creates a three-layer structure. The top layer is UV-resistant and weatherproof, designed to handle years of sun exposure without degrading. The middle layer contains the reinforcing scrim, which gives the membrane its tensile strength. The bottom layer often has a slightly different formulation to improve adhesion or help welding during installation.

Once the membrane is formed, it's cooled, inspected, and rolled into large sheets, usually 10 or 12 feet wide and up to 100 feet long. These rolls are then shipped to job sites where installers will cut and weld them into continuous waterproof systems. We appreciate that this factory-controlled process ensures consistent quality, unlike built-up roofing systems that are assembled on-site with more variables at play.

Key Characteristics of TPO Roofing Systems

Several features set TPO apart from other roofing options. First, the material remains pliable even in cold weather, which helps it accommodate building movement without cracking. This elasticity becomes especially important during temperature swings when roofing materials expand and contract.

Chemical resistance is another standout trait. TPO holds up well when exposed to oils, greases, and industrial chemicals that might be present on commercial roofs. This makes it a smart choice for buildings with rooftop HVAC equipment that could potentially leak or where maintenance activities might involve chemicals.

The seams in a TPO roof are its strongest feature when properly installed. Hot-air welding creates seams that are actually stronger than the membrane itself, which means leaks are less likely to develop at these critical junctions. We've seen older roofing systems fail at the seams first, so this advantage shouldn't be underestimated.

TPO systems typically come with warranties ranging from 10 to 30 years, depending on the membrane thickness and installation method. With proper maintenance, many TPO roofs exceed their warranty periods and deliver 25 to 30 years of reliable performance.

Energy Efficiency and Reflectivity

White and light-colored TPO membranes reflect a significant portion of solar radiation, which directly reduces cooling costs. We've measured surface temperatures on TPO roofs that are 40 to 50 degrees cooler than traditional dark-colored roofs on the same building type.

This reflectivity matters most in warm climates where air conditioning represents a major operational expense. By keeping the roof surface cooler, less heat transfers into the building below. That means HVAC systems don't have to work as hard, which extends their lifespan and cuts energy bills.

Many TPO products meet or exceed ENERGY STAR requirements and qualify for cool roof ratings from organizations that certify energy-efficient building materials. These certifications can help building owners qualify for rebates, tax incentives, or LEED credits depending on their location and project goals.

Durability and Weather Resistance

TPO performs well against several environmental threats that degrade other roofing materials. Ozone resistance means the membrane won't break down when exposed to ground-level ozone, which is common in urban areas. Algae and mold don't easily colonize TPO surfaces, so roofs maintain their appearance and performance over time.

UV radiation is perhaps the biggest threat to roofing materials, and TPO handles it well thanks to built-in UV stabilizers. We've inspected TPO roofs that have been in place for 15+ years and still show good flexibility and minimal surface degradation.

The material also stands up to punctures better than you might expect from a single-ply membrane. While it's not indestructible, TPO's reinforced construction allows it to handle moderate foot traffic and the occasional dropped tool without immediately failing. That said, we always recommend using walkway pads in high-traffic areas to extend the roof's life.

Why TPO Became a Popular Commercial Roofing Choice

TPO entered the commercial roofing market in the late 1980s and early 1990s, positioned as a cost-effective alternative to PVC roofing. Early formulations had some issues, but manufacturers refined the chemistry throughout the 1990s and 2000s, creating the reliable product we work with today.

Cost has always been a major factor. TPO typically costs less per square foot than PVC while delivering comparable performance in many applications. For building owners working with tight budgets, that price difference can be significant when covering thousands of square feet.

Installation speed and safety also contributed to TPO's rise. The lightweight membrane is easier to handle than heavier materials, which reduces labor costs and installation time. Hot-air welding requires less specialized equipment than torch-applied systems, and it eliminates the fire hazards associated with open flames on rooftops.

The energy efficiency angle gained importance as utility costs rose and building codes started emphasizing energy performance. TPO's natural fit with cool roof initiatives made it an easy recommendation for architects and engineers designing new buildings or planning roof replacements.

We've watched TPO's market share grow steadily over the past two decades. It's now one of the most installed commercial roofing systems in North America, competing directly with EPDM and PVC for projects across virtually every building type.

TPO vs. Other Single-Ply Roofing Materials

Understanding how TPO compares to alternatives helps clarify when it's the best choice. Single-ply membranes dominate the commercial flat roof market, but they're not all the same.

| Feature | TPO | PVC | EPDM |

|---|---|---|---|

| Chemical structure | Polyolefin | Vinyl chloride | Rubber |

| Flexibility | High | High | Moderate |

| Reflectivity | Very high | High | Low |

| UV resistance | Excellent | Excellent | Good |

| Seam technique | Heat weld | Heat weld | Adhesive/solvent |

| Longevity | 25–30 years | 25+ years | 15–20 years |

This comparison shows that each material has its strengths. Your choice should depend on specific project requirements, budget constraints, and environmental factors.

TPO vs. PVC Roofing

Both TPO and PVC are thermoplastic membranes that can be heat-welded, and both offer excellent durability. The key difference lies in their chemical composition. PVC contains chlorine and requires plasticizers to maintain flexibility. These plasticizers can migrate out of the membrane over time, potentially causing it to become brittle, though modern PVC formulations have largely addressed this issue.

TPO doesn't need plasticizers because its polyolefin chemistry provides natural flexibility. This makes TPO more environmentally friendly since it contains no chlorine and produces fewer concerns about long-term chemical stability.

PVC generally costs 10 to 20 percent more than TPO, which can add up on large projects. But, PVC offers superior resistance to certain chemicals and animal fats, making it the better choice for restaurants or facilities where grease exposure is likely.

We've found that both materials perform well in most commercial applications. The choice often comes down to budget and specific exposure risks rather than one being clearly superior to the other.

TPO vs. EPDM Roofing

EPDM (ethylene propylene diene monomer) is a thermoset synthetic rubber that's been around since the 1960s. It's typically black, though white EPDM exists at a higher cost. The dark color absorbs heat rather than reflecting it, which is a significant disadvantage in warm climates.

EPDM seams are created using adhesives or solvents rather than heat welding. These seams can be a weak point if not properly installed and maintained. We've repaired many EPDM roofs where seam failures led to leaks, whereas properly welded TPO seams rarely fail.

TPO offers better UV resistance and chemical resistance than EPDM. It's also more puncture-resistant thanks to its reinforced construction. EPDM is slightly more flexible at extremely low temperatures, but for most climates, TPO's flexibility is more than adequate.

Cost-wise, EPDM and TPO are similar, with EPDM sometimes coming in slightly cheaper. But, when we factor in energy savings from TPO's reflectivity, the total cost of ownership often favors TPO over the roof's lifespan.

EPDM remains a solid choice for certain applications, particularly in cooler climates where heat reflection matters less. But for most commercial projects, TPO's advantages make it the more attractive option.

Common Applications for TPO Roofing

TPO works best on flat and low-slope roofs, which makes it ideal for commercial and industrial buildings. We install it on office buildings, retail centers, warehouses, manufacturing facilities, and schools. Any structure with a roof slope of 2:12 or less is a good candidate.

Big-box retail stores are perhaps the most visible users of TPO roofing. Walk through any shopping center parking lot and look up, chances are you're seeing white TPO membranes covering tens of thousands of square feet. These installations benefit from TPO's cost-effectiveness, energy efficiency, and ability to cover large areas with relatively few seams.

Industrial facilities choose TPO when their roofs might be exposed to chemicals, oils, or industrial emissions. The material's chemical resistance prevents degradation that would shorten the roof's life and lead to costly replacements.

Multifamily residential buildings with flat roofs also use TPO, particularly in warmer regions where cooling costs matter. The combination of affordability and energy savings makes sense for property owners managing operating budgets.

We've even seen TPO used on some low-slope residential applications, though this is less common. The material works fine technically, but the large commercial-sized rolls and specialized welding equipment make it less practical for typical house-sized projects.

Installation Methods for TPO Roof Systems

TPO can be installed using three main methods: mechanically fastened, fully adhered, or ballasted. Each approach has advantages depending on the building structure, local wind loads, and budget.

Mechanically fastened systems are the most common. Installers attach the membrane to the roof deck using plates and fasteners, typically placed along the seams where they'll be covered by the next sheet. This method works quickly and doesn't require adhesives, which reduces material costs and speeds installation.

Fully adhered systems bond the membrane directly to insulation boards or the substrate using adhesive. This creates a smooth appearance and provides excellent wind uplift resistance. We recommend this method in high-wind areas or on roofs where aesthetics matter. The trade-off is higher material and labor costs.

Ballasted systems use gravel or pavers to hold the membrane in place. The roof structure must be strong enough to support the additional weight, typically 10 to 12 pounds per square foot. This method costs less for materials and installation but isn't suitable for all buildings.

Regardless of the attachment method, seaming is critical. Installers use hot-air welding machines that heat both edges of the membrane until they melt, then press them together to create a molecular bond. This produces seams that are as strong or stronger than the membrane itself.

We always test seam welds during installation using a probe or by peeling back sample seams. Proper welding requires the right temperature settings, consistent overlap width, and appropriate roller pressure. When done correctly, TPO seams will outlast the membrane and remain watertight for decades.

Conclusion

TPO roofing, Thermoplastic Polyolefin, has earned its position as a leading commercial roofing solution through a combination of performance, cost-effectiveness, and reliability. We've seen it prove itself across thousands of installations in varied climates and applications.

The material's blend of polypropylene and ethylene-propylene rubber creates a membrane that balances flexibility with strength. Its reflective surface cuts cooling costs, its welded seams resist leaks, and its chemical composition stands up to UV radiation and environmental exposure better than many alternatives.

When comparing options for flat or low-slope commercial roofs, TPO deserves serious consideration. It costs less than PVC while delivering comparable performance in most situations. It outperforms EPDM in energy efficiency and seam strength. And its proven track record removes the uncertainty that comes with newer, less-tested materials.

For building owners and facility managers planning roof replacements or new construction, understanding what TPO stands for goes beyond just knowing the acronym. It's about recognizing a roofing solution that delivers value over decades, not just at installation. We've found that informed decisions lead to better outcomes, and TPO often emerges as the smart choice when all factors are weighed.

What does TPO roof stand for?

TPO roof stands for Thermoplastic Polyolefin roof, a single-ply roofing membrane made from a blend of polypropylene and ethylene-propylene rubber. It's widely used on commercial flat and low-slope roofs for its durability and cost-effectiveness.

How long does a TPO roof typically last?

A properly installed TPO roof typically lasts 25 to 30 years with appropriate maintenance. Warranties range from 10 to 30 years depending on membrane thickness and installation method, though many systems exceed their warranty periods.

Why is TPO roofing more energy-efficient than other materials?

White and light-colored TPO membranes reflect significant solar radiation, reducing roof surface temperatures by 40 to 50 degrees compared to dark roofs. This reflectivity lowers cooling costs and reduces HVAC workload, especially in warm climates.

What's the difference between TPO and EPDM roofing?

TPO is a thermoplastic membrane with heat-welded seams and high reflectivity, while EPDM is a thermoset rubber with adhesive seams and typically black coloring. TPO offers better UV resistance, energy efficiency, and stronger seams than EPDM.

Can TPO roofing be installed on residential homes?

While TPO technically works on low-slope residential roofs, it's less common for houses. The material comes in large commercial-sized rolls and requires specialized welding equipment, making it less practical and cost-effective for typical residential projects.

How much does TPO roofing cost per square foot?

TPO roofing typically costs less per square foot than PVC while delivering comparable performance, usually 10 to 20 percent cheaper. Exact pricing varies based on membrane thickness, installation method, and regional labor rates for commercial applications.